"The greatest impact of BI has been on our manufacturing operations. Supervisors use the Efficiency and Utilization Report to address training, points of constraint, combining operations, etc. We adjust as we go, making our response much closer to the actual event, which has increased production an estimated 10%." - - Elgin Fastener Group

Per their website, Elgin Fastener Group (EFG) is the largest American made, single-source supplier of specialty fasteners in the nation, and the leading provider of system-critical engineered fastening solutions. They deliver the most innovative parts available to help grow businesses with just-in-time operation, consistent quality, and streamlined ordering process.

BI to Measure and Manage Performance

As a portfolio company of a private equity firm, Elgin Fastener Group was encouraged to roll out a business intelligence solution to better measure and manage performance against their value-creation plan. They engaged Blue Margin for their experience in the manufacturing industry and expertise with Power BI, Azure, and SQL. Previously, EFG used their ERP, Epicor 10, to run reports for their quoting and sales processes. This provided helpful insight but often required further ad hoc reporting and manual analysis to make decisions and improve processes.

Epicor and Excel Data into Dashboards

To improve the impact and efficiency of their reporting, Blue Margin organized EFG’s Epicor data into a reporting database that feed dashboards for single-screen visibility into Backlog Sales Projections, On-Time Delivery, and Inventory. Additionally, a calendar view of bookings was added and displayed on the manufacturing floor to help front line workers stay on top of fulfillment timelines.

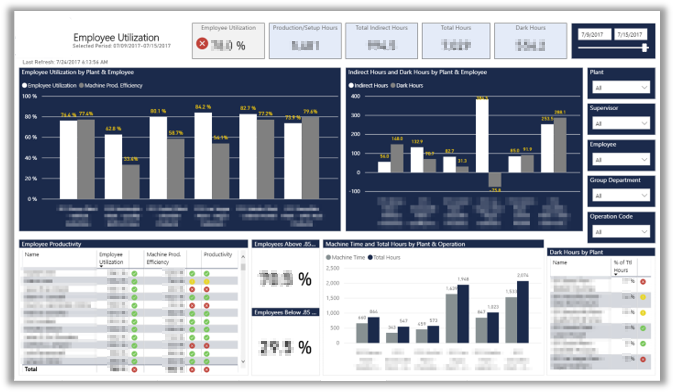

Additionally, their Efficiency and Utilization reports, which were cumbersome Excel workbooks, were converted to intuitive dashboards. This new reporting replaced their monthly retrospective view with a daily, real-time view.

Reporting to Advance Business Goals

According to Jim Pastor, VP of Information Systems, the greatest impact of their data analytics and dashboards is on manufacturing productivity.

Real time dashboards allow supervisors to stay current on Efficiency and Utilization report every morning to determine which technicians would benefit from more training, identify points of constraint, and pinpoint where they could combine two operations into one to increase efficiency.

I really like the way Blue Margin methodically approached the project. You leveraged our existing Excel data to capture all calculations. The cadence of the progress meetings and the PM process was done really well. You always focused on how your work would meet our business needs.

Jim Pastor, Elgin Fastener Group